Sustainable personalised T-shirt printing for your business or brand.

Sustainable personalised T-shirt printing for your business or brand.

Professional digital mockups and every order checked by an expert as standard. You can expect retail-quality T-shirt printing and a service like no other.

Trusted by the worlds best:

Custom T-shirt printing

Don't settle for ordinary, experience premium custom T-shirt printing, with retail quality production as standard. Some of the UK’s biggest brands and organisations trust A.M. Custom Clothing, here’s why you should too.

No minimum order

No matter how big or small your business is, we can help.

Premium standards

Industry-leading machinery, inks and threads mean retail quality, every time.

Built on sustainability

From day one of business it’s been our focus, it's in our DNA.

Responsive support

Our team of print and design experts are here to support you every step of the way.

When speed matters

Our pioneering technology means you can order online, or get a quote in seconds, 24/7.

T-Shirt printing with A.M. Custom Clothing

Whether you need merchandise, uniforms, or promotional items, custom printed T-shirts are a great place to start. The affordability of tees makes them an ideal promotional tool, perfect for any business.

We’ll cover everything you need to know when it comes to getting your design or logo printed on T-shirts and look at the best decoration method for you.

If you need as little as 1-25 personalised T-shirts, you can use our Online T-Shirt Designer. Or if you’re after more than 25, you may prefer to Get a Quote for T-Shirt Custom Printing.

T-shirt printing decoration methods

When it comes to custom-printed T-shirts, there are many different decoration methods available. Our team of experts will always be on hand to help you select the most suitable T-shirt printing option based on your design complexity, garment fabric and order quantity. To help, here’s an overview of the T-shirt print methods we offer.

Screen printing

This is one of the most commonly recognised print methods for bulk production. If you need 50 to 25,000 T-shirts printing, screen printing is likely to be the most suitable print method. Learn more about our screen printing.

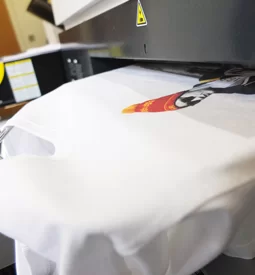

DTG printing

Direct-to-garment (DTG) printing T-shirts is ideal for those with highly detailed design work such as full-colour photographs, or those requiring small order volumes. Learn more about our DTG printing.

Vinyl printing

Vinyl transfers are ideal for printing simple designs onto clothing. Vinyl printing is more suitable for designs with one or two colours, rather than full-colour designs. Learn more about our vinyl printing.

Digital transfer printing

Digital transfer printing for clothing is perfect for when you need a complex design printed quickly and economically onto fabrics unsuitable for other print methods. Learn more about our digital transfer printing.

Embroidery

Custom embroidery is the process of stitching your design into clothing using a needle and thread. Embroidery is stitched directly onto the fabric, ensuring maximum durability and adding a textured dimension to your design. Learn more about our embroidery service.

All-over printing

For all-over T-shirt printing, we use a process called dye sublimation printing and unlike other print methods, this process enables us to print your design across the entire t-shirt. Learn more about our all-over printing.

Unsure of which decoration method to choose? Don't worry, our experienced team will ensure you get the appropriate print method for your order.

How much does printing on T-shirts cost?

The price of custom T-shirt printing will vary depending on a number of factors. These include:

How many products you purchase

The T-shirt you select

How many colours there are in your design

How many different places on the T-shirt you want to decorate

The print method you opt for

A single printed T-shirt could be as much as £13, however, when ordering 100 the price could be as little as £3.50 per item.

Sustainable, quality garments

We cover all bases, with products made from natural fibres like organic cotton and recycled cotton, right through to synthetic options such as recycled polyester. Through this broad range of fabric options, we offer the widest range of environmentally and ethically sourced printed T-shirts in the UK and Europe. This ensures you can access the products you need without compromising on your values.

Our most popular T-Shirts

We’ve got a huge range of T-shirts ready for you to print with your design….

If you need a middle ground between sustainability, ethics and price, this is the product for you.

If organic materials and ethics are your priority, this is the product for you.

If sustainability & ethics are your priority above everything else, this is the product for you.

If you’re looking for sports T-shirts made from recycled materials, this is the product for you.

If you’re looking for T-shirts made from recycled cotton, this is the product for you.

Other popular T-shirt styles available for printing:

Vests & Tanks | Kids T-Shirts | V-Neck | Organic | Sports T-Shirts | Crewneck | Long Sleeve | Oversized T-Shirts | Heavyweight T-shirts | View all T-shirts

Not sure which T-shirt to choose?

Find your perfect T-shirt, with our Product Finder Tool. Or view our full range of T-shirts.

T-Shirt Printing for the world's best brands

We’re proud to have partnered with some of the biggest brands in Europe. Get inspired with case studies from some of our other customers' customised T-shirt printing below.

World Merit

Find out more about how we helped connect a global community of change makers through screen printed T-shirts. >>

YOOX Net-A-Porter

Find out how we produced screen printed T-shirts for the world's leading online luxury fashion retailer. >>

Ready to print custom T-shirts?

Frequently asked questions about custom T shirt printing

Working out how many items you need early on is critical to getting the most accurate quote from your T-shirt printer. The quantity has a huge influence on the production method, and in turn can make a huge difference in the price.

If you’re aiming to simply buy as many T-shirts as you can within your budget, it’s worth advising us of the budget, so we can then provide you with the best suitable options to get the most out of your budget.

If you also want samples, knowing the quantity or budget for the bulk order to follow will also ensure you know what production method will be used on the bulk order; so you’re able to ensure the same is used on the sample (where possible).

Conversely, it’ll ensure you’re aware if there will be a different print method used on your bulk order vs the samples. You can find more information on this in our Help Centre article Print methods used on samples vs bulk orders.

This really depends. Sometimes, it’s best to opt for screen-printed T-shirts, while other times DTG is best. It comes down to a lot of factors, such as the artwork, the fabric composition, and the quantity you want to purchase.

At A.M. Custom Clothing, our expert team will generally choose the most suitable print method for your logo or design, depending on your artwork and quantity requirements. This is because we believe you shouldn’t need to be a print expert to order custom-printed T-shirts, that should come as part of the service.

Regardless of the print company you use, we only advise choosing the print method yourself if you have experience with textiles and garment printing, or have a particular finish in mind. If you have no prior experience in this field we advise leaving the print choice down to the experts who are printing T-shirts every day.

With this in mind, it’s typically best to leave the print method of choice in the hands of your T-shirt printer, to ensure you get the best results.

At A.M. Custom Clothing, we offer a lot of cost-effective options to help our customers that have tight budgets. However, when you’re comparing prices for T-shirt prints online, it’s important to remember that companies offering exceedingly cheap T-shirt print prices can only do so by cutting corners in quality, customer service, and/or ethics.

Contact our team today to see how we can make your budget stretch as far as possible without sacrificing the other factors you care about.

It is possible to make your own printed custom T-shirts at home as there are plenty of print machines for T-shirts on the market. However, this is just like any other profession you can do yourself, but, it takes longer and doesn’t typically yield the same great results.

We use some of the most advanced equipment for custom printing T-shirts and we also have some of the most skilled people to print T-shirts in our UK facilities, so you can be sure you’re getting the best quality when you buy from A.M. Custom Clothing.

Not only that, but you don’t need to spend money on equipment or stress about getting things right. Just place your online T-shirt printing order through our shop or request a quote from our team and we’ll take care of the rest.

While logo printing on T-shirts has been around for centuries, the ability to print photos on T-shirts is a relatively new one. But we have several great print methods available that allow us to deliver great results when photo printing on T-shirts.

There is no one-size-fits-all print method for T-shirt printing. Sometimes screen printing will be best, while other times DTG may be more appropriate. If you’re looking for all over T-shirt printing, then you’ll need to use sublimation.

Each method has its own pros and cons, so at A.M. Custom Clothing we offer a wide range of different options. Factors like the T-shirt’s fabric, the number of colours, and the order size will all influence the decision on which method to use.

That’s why we make things easy for you by choosing the right method for you. Just tell us what you need and we’ll take care of the rest.

The cost of printing anything onto a T-shirt depends on several factors. Firstly, the number of T-shirts that you’re producing will be one of the biggest influences, while the number of colours and the complexity of your design will be another.

These factors will change the print method that is used, with DTG being best for small orders with lots of colours/complexity, while screen printing is better for larger runs.

A single printed T-shirt could be as much as £13, however, when ordering 100 the price could be as little as £3.50 per item.

Thankfully, it’s easy to calculate the cost of printing a T-shirt when you use our online shop. Just choose the T-shirt you want and add your logo or other artwork. The designer will then automatically calculate the price based on the quantity you’ve selected.

Alternative, you can request a quote if you’re buying more than 25 units and you’ll receive a price in your inbox in just minutes.

If you want to know more, we have put together a detailed breakdown of the factors that influence the cost of a printed T-shirt that can make it easier to understand.

Most T-shirts are made from cotton or a blend of cotton and polyester. Generally, cotton is the most appropriate fabric as it provides a balance between breathability, softness, cost, and quality.

High-quality cotton is also the most versatile when it comes to printing. Fabrics like polyester can generally only be printed using screen printing, while cotton can also be DTG printed.

Polyester is a synthetic fibre that’s mainly used for sportswear. It is generally lighter, more breathable and will dry faster than cotton.

Other materials like bamboo and rayon each have their own pros and cons. It’s not that one offers better quality over the other, but they each have scenarios for which they are best suited.

Some companies charge set up fees for producing printed T-shirts. This may be for setting up a machine, creating screens, or other costs. You should always check that the printer you’re using has included all of these charges in their quote.

We prefer to keep things simple, we don’t charge setup fees, and you can even place your printed T-shirts order online.

Oversized t-shirts are becoming increasingly popular, not just as a fashion item, but also for brands looking to provide fashion-forward options for uniforms and merchandise. Check our guide for personalised oversized t-shirts if you're unsure about what's available or whether they're right for you.

Ideally, you want to ensure your logo is in vector format, however, if you’re placing a smaller order, then a high-quality PNG may do the job. If you’re unsure, we’d recommend looking at our T-shirt printing artwork guide, to find out what format your artwork should be in. You’ll also be able to find print-ready templates for your artwork there too.

Screen printing is still the most commonly used print method when creating T-shirts with your logo or other design on them. However, new technologies have been changing this over the last few years.

Using a method known as Direct To Garment (DTG) printing, it is possible to produce great-looking prints with as many colours as you like on small quantities.

At A.M. Custom Clothing, we offer a wide range of different print and embroidery methods for your T-shirts, though we’ll generally select the most appropriate one for you based on the unique nature of your order.

This means you don’t need to be a printing expert to decide what one is best for you, you just need to tell us what design you want to print and onto which T-shirts and we’ll take care of the rest.

If you do have a particular print method in mind, then be sure to let us know and we can let you know if it is suitable.

If you’d like to learn more about screen printing, our handy guide can tell you everything you need to know.

The time it takes to print 100 T-shirts can vary on the method used, the design(s), and the number of colours. However, this would take a couple of hours from start to finish.

Our lead times depend on more than just the physical time it takes to produce the garments though. You need to stock to arrive from the manufacturer, everything to be counted and checked, and then packed up again ready for shipping.

Lead times will also depend on what else is in the current print queue. This is why we suggest leaving 14-21 days to receive your order, though it’s always best to check the lead time when placing your order.

Producing high-quality T-shirts depends on several factors like the design work, the quality of the fabric being printed on, the machinery used, the ink, and the skills of the person doing the printing.

At A.M. Custom Clothing, all we do is print (and embroider) T-shirts, sweatshirts, hoodies, polo shirts, and just about any other garment you can think of. So you can be sure you’re in safe hands.

If you’re thinking about starting a business to sell T-shirts online, then there are many things you will need to consider. You aren’t the first person to have this idea, so it’s important that you are realistic about your prospects and find ways to make your business stand out from the rest.

We have also put together a number of guides to help new businesses when thinking about producing their own clothing to sell online:

- How to design a great logo for your business

- How to improve your online store

- Should you choose printing or embroidery?

- How to choose the right T-shirt

- How to keep costs down when starting a T-shirt business

- How to build a sustainable and ethical fashion brand

- A guide to relabelling for startup fashion brands

- How to start a fashion brand

Like with anything else in life, if you put in the effort, you will increase the likelihood of your T-shirt business being profitable.

There are several different types of machines that you can use for printing T-shirts, though the two main ones are screen printers and DTG printers.

DTG printers work similarly to the inkjet printer you have at home, while industrial screen printers can take up entire warehouses and look a bit like mechanical octopi.

We use some of the most advanced printers in Europe when producing printed T-shirts for our customers, so you can be sure you’ll be getting the best quality. So there’s no need for you to invest in expensive equipment.

At A.M. Custom Clothing, we’ll take care of it for you. Just place an order through our online shop or request a quote to get started.

If you're looking for UK T-shirt printing, we can help. We have a number of production hubs across the UK, so whether you're in Chester, London, Birmingham, Manchester, Glasgow, Cardiff, Bristol or anywhere in the UK we can help with your T-shirt printing.

How to place your order:

Need a small order of less than 25 personalised T-shirts?

If you're placing a smaller order of less than 25 T-shirts, our online shop is the best way to place your order. Just select your preferred T-shirt, add your design or logo and then place your order. It is as easy as that! If you get stuck, we have a handy guide here.

Small order benefits:

Easy online design tool

No minimum order

Every order checked by print experts

Premium retail quality threads & inks

Need a bulk order of 25 or more printed T-shirts?

If you're placing a larger bulk order of 25 or more custom T-shirts, head over to our simple quote request form, let us know what you want and we'll have a quote in your inbox within seconds. After we've answered any questions you may have and have everything as you need it, we'll produce digital mockups for your approval before your order goes into production.

Bulk order benefits:

Bulk order discounts

Dedicated account managers

Wide range of customisation options

Premium retail quality threads & inks

Behind the scenes

You can get a behind the scenes look at all of our market leading print technology in the video below.

How many products do you need?

We keep things simple, just select the quantity you need below, and our experienced team will ensure you get the appropriate print method for your order.

1-24 items

For both print & embroidery our Online Shop is the fast & easy way to order. All custom orders (of any size) come with a professional digital mockup before anything goes to production.

25-999 items

If you require a quote for 25 or more items, head this way. Whether it's for bulk t-shirt printing, or embroidered workwear we can help.

1000+ items

Need commercial volumes? Get in touch with our team, and join some of the world's biggest brands who rely on us for their branded clothing.

Print On Demand

Whether you're a startup brand, or a charity looking to sell merchandise, we provide an easy, risk free way to sell t-shirts online. Fulfilment on bulk orders also available.

Want to use a specific print process?

If purchasing custom printed T shirts, our system will use a number of variables to calculate the best and most appropriate production process. This keeps things nice and easy for you, and ensures you don’t have to spend years gleaning the knowledge of a printer before making your order. Your order is then checked over by our expert team, ensuring the most appropriate process has been assigned and that your artwork is in the suitable format. Please note all of our print processes are of the highest quality and durability, so perfect for whatever you need. If you do require a specific print method to be used, you’ll find details on how to do this & more information here.

Popular locations we serve

We're often asked 'do you offer T-shirt printing near me'. We’ve worked hard to ensure that we can serve you no matter where you are in the UK. We operate nationwide, as well as having the capacity and infrastructure to serve clients across Europe and the rest of the world. Some of our most popular shipping destinations include:

Turnaround times for the UK and worldwide

We can print thousands of personalised T-shirts per day and are fortunate to be one of the UK’s leading suppliers, to some of the biggest and best brands. This means we typically have a lot of orders being produced at any given time. For our most up-to-date lead times head over to help centre where you'll find our current turnaround times, for a clearer idea of how quickly we can and we can bring your custom vision to life.

Featured in:

"The go-to supplier for ethical and environmentally sound custom clothing & branded uniforms."

"Leading the way in Fairtrade with A.M. Custom Clothing"

"Another business with a canny growth strategy is Chester based, A.M. Custom Clothing, which provides personalised, printed garments."

"What sets this company apart is their option of fair-trade, organic and recycled garments to choose from"