Screen printing has always been a popular way to print different designs quickly and easily. This method is used at school and colleges for art projects and in businesses to print their logo or contact details on t-shirts for merchandise, as well as for retail ready clothing products.

We will start off with a little history of screen printing. It is a technique where mesh is used to transfer ink to other materials and it first appeared in China almost 2000 years ago. Other Asian countries decided to adapt the technique and create new methods of screen printing. The technique grew and moved to Western Europe, but this wasn’t a popular method until silk mesh was available to trade enabling printers to create a profitable outlet.

The technique hit England in the 20th century and it became mainstream with Andy Warhol using the method on his famous Marilyn Monroe print.

Today’s artists and businesses use the mesh screen printing and use practice prints to make sure the colours are all lined up correctly. This enables printers to double check that their final prints are going to be good quality. Coloured inks are applied to the print before the finished prints are placed on a large dryer. The technique can be used to print multiple items in a single run.

Creating The Screen Print Mesh

To create the mesh screen, it is simple. All you need to do is mix water and sensitiser, and mix the solution with the emulsion of your choice. Pour the final mix into a scoop coater and evenly spread it on both sides of the mesh, dry the emulsion, place your design on the mesh, dry it and wash off the unexposed emulsion.

Print Your Design

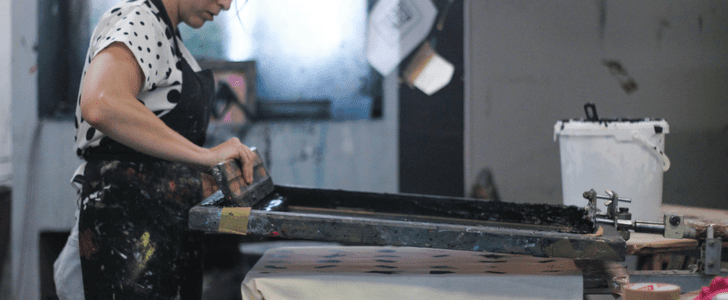

To print the design by hand, all you have to do is place the design on the shirt you wish to print on, add a thick layer of ink below the design and spread across the mesh evenly with a squeegee. Lift up your mesh frame and then reveal the printed design.

Repeat The Process

This can be done over and over to create a variety of different shirts with the exact same logo or artwork on it.

Creating Designs For Screen Printing

Your artwork can be designed by hand or on a computer. As long as you can scan your hand drawn piece and print it, you can use whichever design technique you prefer. Don’t forget to print it on the translucent film so you can transfer it to the emulsion mesh.

Screen printing is used for printing in bulk; it is rare for someone to set up screen printing and use it for just one shirt, there are better print methods for single units, such as DTG or Digital Transfers. The cost of printing doesn’t have to be as high as some people think.

Choosing the colour of your ink and shirt is also important due to the fact you need to stop the colours clashing. Colours also help the design stand out. A popular design is either a grey shirt or a white shirt with black ink, this guarantees that the design will be clearly shown, especially if you’re using this for business branding, and you want your business details to be clearly displayed.

To make a successful print, make sure your print technique is correct. It needs to be printed on a transparent film sheet which will give you the best results. To make a design clear, the bolder the writing, details or design, the better, so that the emulsion that isn’t exposed will be big enough to make the design clear with high quality prints.

The Advantages And Disadvantages Of Screen Printing

Screen printing provides a lot of benefits but, like most forms of printing, there are also some potential disadvantages too. Here, we’ve provided you with a list so that you can determine whether silk screening is right for your requirements.

Benefits:

- The prints are long lasting due to the composition and thickness of the inks used in the screen printing process. The prints can withstand more stress without getting damaged, fading or losing the quality of the print.

- It is helpful for anyone who wants to create more than one item.

- The printing process creates a great finish for a print. You enjoy vibrant colours that don’t fade and are hard to replicate on alternative printing methods.

- The more ink the better. Screen printing allows you to have thicker ink on your shirts, this sounds a bad thing, but it makes for greater results.

- It is a very versatile print method. It can be used on any surface as long as it’s flat, fabric, wood, and plastic, even metal. It’s most common use is producing screen printed clothing, such as t-shirts.

Disadvantages:

- Although screen printing is ideal for large projects and multiple prints, it isn’t convenient for small projects.

- The more colours, the greater the expense. More colours not only means more ink, but more mesh and other printing products. Cutting corners, in this respect, means that colours can bleed and mix when you don’t want them to.

- Screen printing is an easy way to create great quality prints, but it can sometimes be complicated, depending on if you’re going to add different colours or you have created a complicated design.

In conclusion, screen printing is an incredible way of creating great prints. Whether you want to craft school projects or business merchandise, it is a simple way of getting perfect prints. It’s one of the best techniques used by artists and printers.

Guest Author BIO:

Screen Stretch offer a wide range of screen printing supplies to businesses, schools, colleges, artists, print makers, hobbists and those starting out in screen printing at home.

Disclaimer:

A.M. Custom Clothing does not purchase products from, nor endorse, Screen Stretch.

If you would also like to write for us as, find out how on our guest blogger page.

* Find this article useful?

Sign up to our newsletter, for the latest news, resources, trends and exclusive discounts.

Join our newsletter

If confirmation doesn't arrive in your inbox following subscription check your spam/junk mail.